They can withstand high temperatures, are hygienic and reduce product sticking: Our rod network belts are ideally suited for use in the baked goods industry. No wonder that our customer also opted for these conveyor belts. Previously, he used the ECO rod network belts, which are even suitable for ovens with temperatures of up to 250 °C.

Best Practice

Marathon instead of sprint

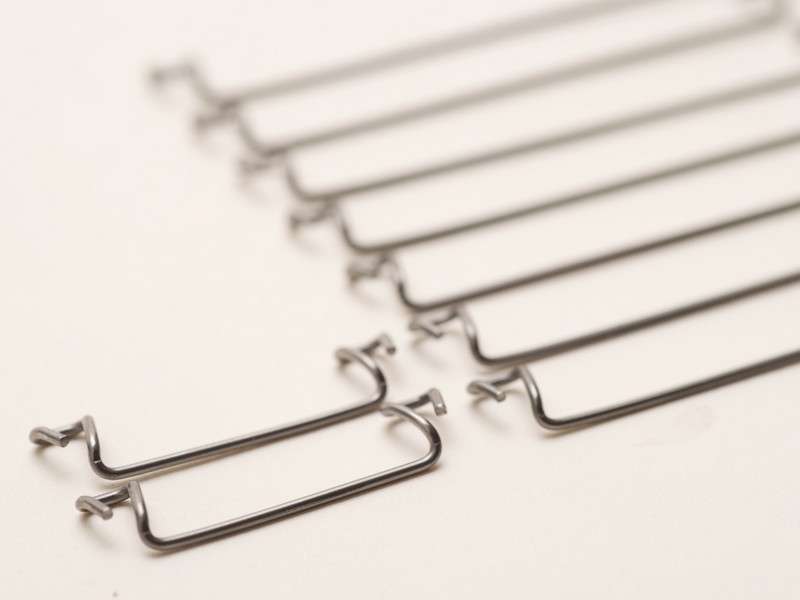

Material change from ECO to ELT

But now the downtimes were to be reduced. Previously, the lines had to be stopped for longer periods, for example in the event of a breakdown or a belt change. In these situations, new connecting wires had to be expertly braided in - professional work was required here, which took a corresponding amount of time. Our colleague Dietmar Hessel, Area Sales Manager East, had the right solution ready:

"In consultation with our customer, we converted the lines to ELT. This design offers similar advantages as the ECO belts. However, the service lives can even be doubled. "