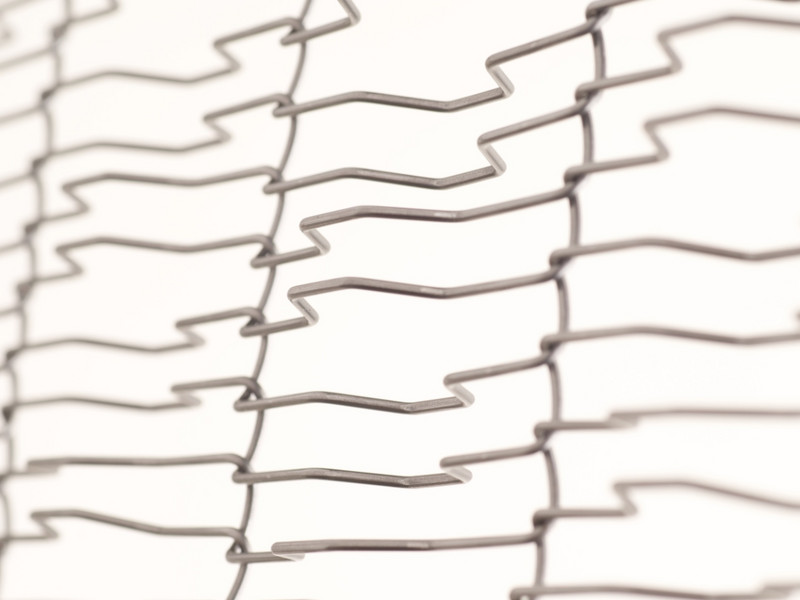

Our customer, who among other things produces cakes, used the rod network belts ECO in the enrobing process to coat the baked goods with chocolate. But during this process, a large amount of chocolate also got stuck on the bottom. This would hardly have bothered consumers, but it did cause problems during packaging. When asked about this, our Märtens sales representative on site recommended that the ECO rod network belt be provided with additional inserted points.

Best Practice

Nothing sticks there:

Optimization of the stalling process

The effect is clear: The points reduce the contact area of the cake base on the belt and thus also the amount of chocolate that can stick to the cake base. The unwanted adhesions could thus be minimized, which in turn simplified the packaging processes.

Top features of our rod network belt ECO:

- Thin, flexible and lightweight belt construction

- Forced guided

- Economical solution for standard applications

- Permeable construction

- Hygienic construction

- Small deflection radii

- Stainless steel design approved for foodstuffs according to VO EG 1935/2004

By the way: In addition to points, our rod network belts can also be equipped with guide chains or carriers.