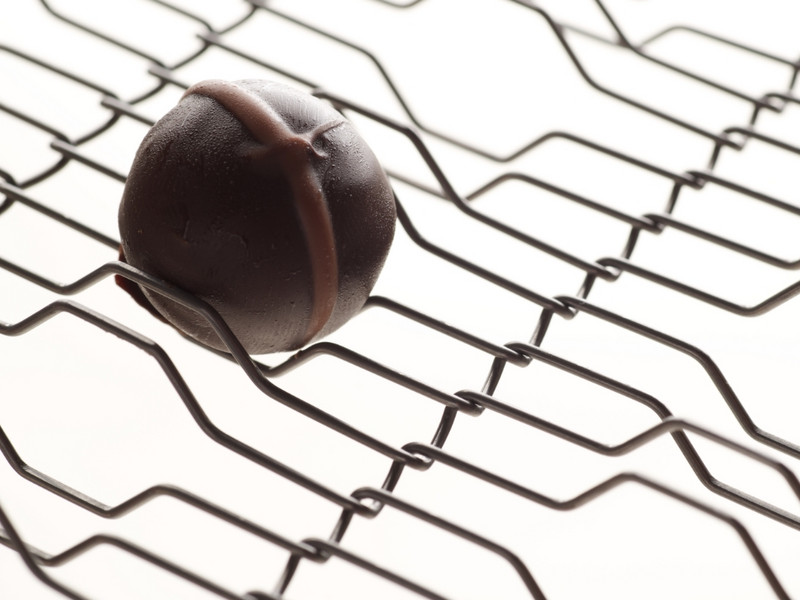

One of our customers, a major manufacturer of chocolate-covered cookies with fruit jelly filling, also benefited from this. A rod network belt made of stainless steel 1.4310 was previously used in production, an economical solution for a wide range of standard applications.

Runs and runs and runs...

Extended service life thanks to K2390

However, after only a short running time of around two weeks, the material showed the first signs of breakage. The result: downtime due to necessary repairs and belt changes. Our experts took care of the problem and identified the cause of the damage. Citric acid contained in the jelly led to brittleness of the material and ultimately to breaks.

K2390: innovative and robust To counteract this, we recommended the use of our special material K2390, which has significantly better resistance to acids and alkalis. Of course, this innovation is VO EG 1935/2004 compliant and therefore suitable for food. The effect of the material change was immense: With the used rod network belt ECO made of the material K2390, the service life could be increased to 12 weeks and the customer was thus also able to considerably reduce the downtimes on the production line.

Read more about rod network belts and our innovation K2390 here: