- Specialised Conveyors

Description

TOP features

- Variable product spacing

- Hygienic construction

- No changeover necessary when changing products

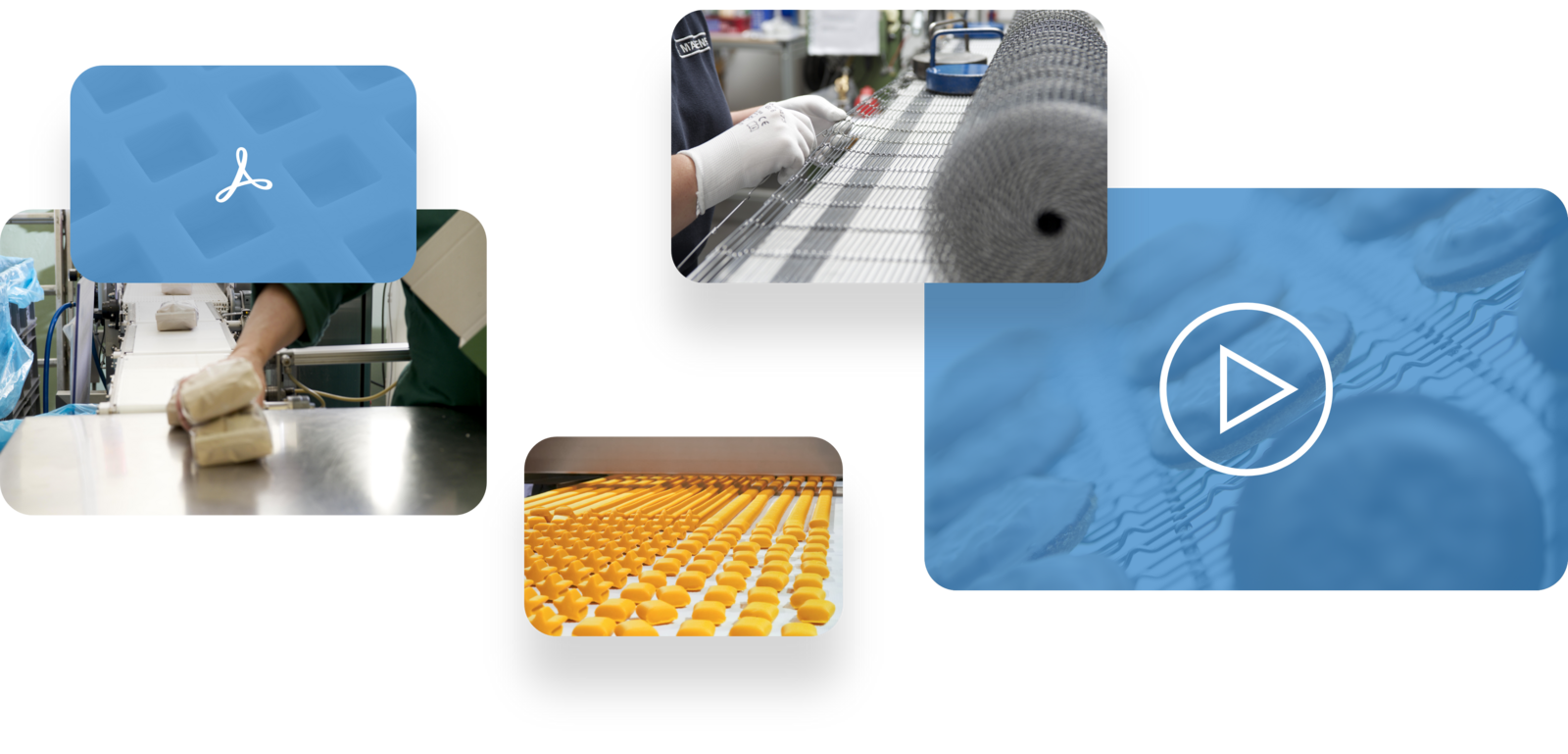

Typically, our spreading conveyor system with variable spreading is used for pick & place applications. However, it may also be necessary to bring products together or separate them in the production or packaging process or in front of enrobing systems. The highlight of this system is that the spreading range can be variably adjusted from 0 to 30 % manually or motor-driven, even during transport. Another advantage of this design is the small deflection diameter of only 40 mm - an aspect that is especially important for the transport of small products. Converting the system when changing products is thus a thing of the past. A clear plus in terms of flexibility and efficiency!

The closed belt surface is particularly hygienic and due to the silicone coating, the products do not stick to the material. Depending on your requirements, this system is optionally available with castors or machine feet. The machine frame and the chain cover are made of stainless steel 1.4301. An adjustable belt speed by frequency converter and an integrated transfer table for very small products are optionally available.

Industries

- Baked goods

- Confectionery industry

- Food

Application areas

- Before coating plants

- Before packaging plants

- Separating or converging products in the production or packaging process

- “Pick and place” applications

Materials

- Elastic fabric with silicone coating

min. Temperature

+10° C

max. Temperature

+50° C

Speeds

- Constant belt speed (up to 25 m/min)

Equiptment

- With castors or machine feet

- Machine frame and chain cover from stainless steel 1.4301 (304)

optional equiptment

- Expansion range machineadjustable

- Variable belt speed through frequency converter

- Integrated transfer table for very small products

Dimensions

- Deflection diameter: 40 mm

- Adjustable expansion range from: 0 bis 30%

Videos

Downloads

Tech. drawings / sketches / data tables

Equipped for every production step

Gradient, incline or curves, transport of very small products or larger items: We have the right conveyor belt for almost every process in production. With our special machines - more precisely the Expanding conveyor system and the Expanding conveyor system with variable spreading - we complete our product range. We have incorporated our experience in the production of separating belts into our design of the special-purpose Expanding conveyor system. They are therefore the perfect complement for demanding production processes.

The field of application of our special machines is quickly explained: They are used wherever it is necessary to bring products together or separate them. There is no limit to the number of product series that can be transported. But how does it all work? A row spacing is changed by the forced guidance of the separating belt with a special link chain in the side area - during transport, the separating belt is stretched transversely to the direction of travel, thus also increasing or decreasing the row spacing of the products. Customers often ask us: Should I choose a separating belt system or a separating belt system with variable spreading? The classic Expanding conveyor system is the perfect solution for fixed production processes, the Expanding conveyor system with variable spreading can be adjusted to different requirements.

Of course, our product portfolio also includes the appropriate conveyor belts for the Expanding conveyor systems. These consist of a transversely elastic fabric with a silicone coating. In addition, we also offer our customers the separating belt LW, a material innovation developed by us. This has a reduced force absorption, so that belt installation is made considerably easier and downtimes can also be reduced during belt changes.