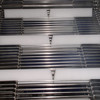

- Rod network belts

Description

1.1211 spring steel wire, type DH (AISI 1060):

Used when there are no demands in terms of corrosion resistance, e.g. with chocolate enrobing machines. Temperature range from -10° C to +70° C. Available wire diameters: 1.00 / 1.25 / 1.40 / 1.60 / 1.80 mm

1.4310 stainless steel wire (AISI 302):

Used where corrosion resistance under normal conditions is desirable, e.g. in the fish and meat industry. Temperature range from -50° C to +250° C. Available wire diameters: 1.00 / 1.25 / 1.40 / 1.60 / 1.80 / 2.00 / 2.35 / 2.80 mm. Approved for use in food processing per VO EG 1935/2004

K2390 stainless steel wire:

Used if a high level of corrosion resistance is required, e.g. with fruit acids. Temperature range from -80° C to +280° C. Available wire diameters: 1.00 / 1.25 / 1.40 / 1.60 / 1.80 / 2.35 / 2.80 mm. Approved for use in food processing per VO EC 1935/2004.

All wires high-gloss polished: Reduction of product adhesion to smooth surface due to low-impact wire processing.

Materials

- 1.1211 spring steel wire

- 1.4310 stainless steel wire

- K2390 stainless steel wire

Accessories

- Possibilities to connect rod network belts

- Splicing tube

- Sprockets for rod network belt

- Transfer disc

- Transfer element

- Transfer profile

- Transfer roller

Can be combined with

- Carriers

- Guide chains

- Points

min. Temperature

-80° C

max. Temperature

+280° C

Speeds

- Up to 15 m/min.

Dimensions

- Up to 4000 mm wide, and above in special cases.

Videos

Downloads

- Instructions for endless splicing ( PDF 373.02 KB )

- K2390 ( PDF 226.33 KB )

- Manufacturing tolerances ( PDF 57.83 KB )

- Possible causes for insufficient service life ( PDF 1.72 MB )

- Product inquiry ( PDF 216.02 KB )

- Rod network belt with carriers ( PDF 626.63 KB )

- Rod network belt with guide chain ( PDF 489.87 KB )

- Rod network belt with points ( PDF 465.74 KB )

- Rod network belt – instructions for endless splicing ( PDF 482.19 KB )

- Technical details ( PDF 247.79 KB )

- Product data sheet

Tech. drawings / sketches / data tables

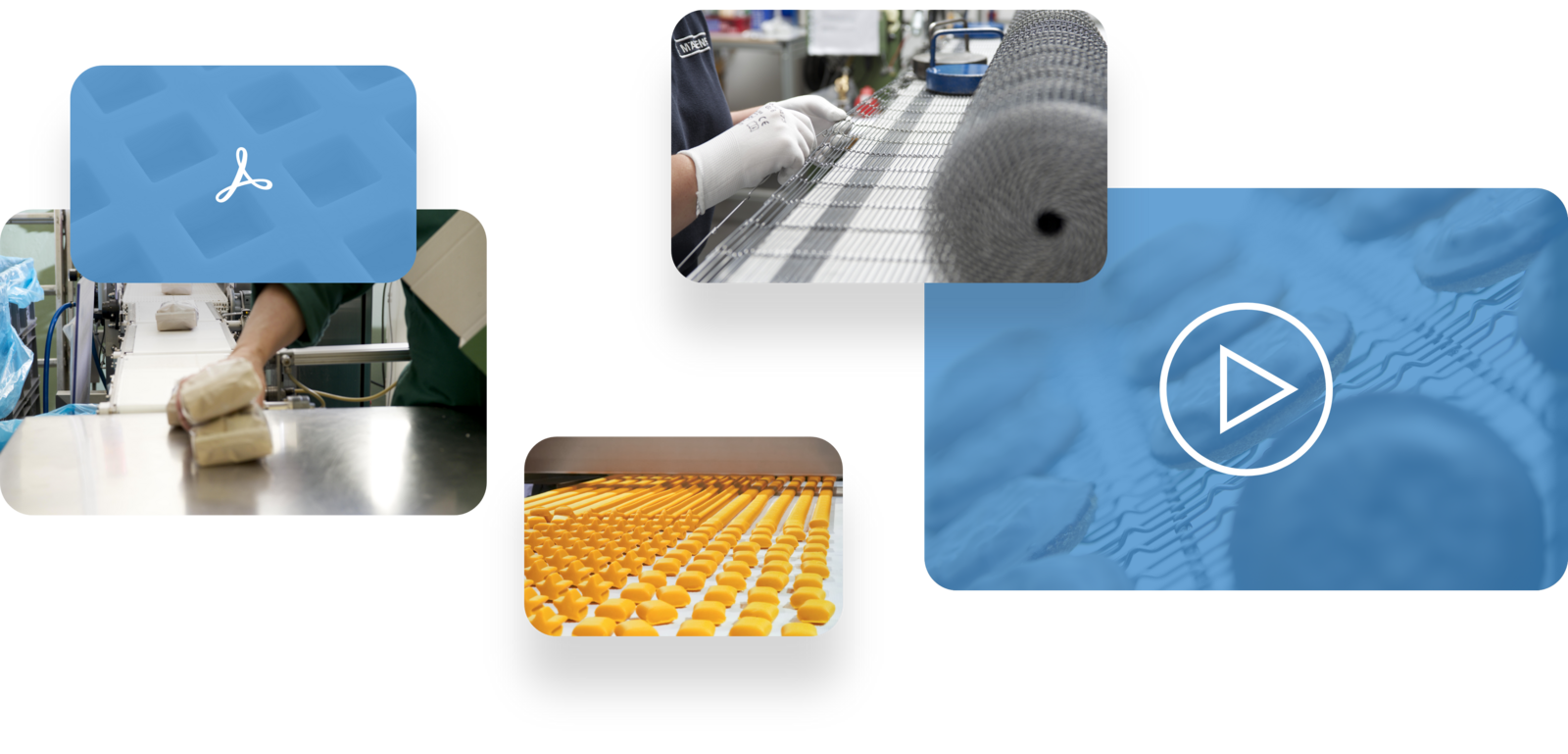

The rod network belts are real all-rounders - and of course food-approved in accordance with VO EG 1935/2004. Depending on the material class, they meet the most diverse requirements and can be used for a wide range of processes. A characteristic feature of this product category is its permeable and particularly hygienic design, which makes it the ideal choice when it comes to enrobing, glazing and spreading processes. But rod network belts from Märtens are also convincing in baking ovens, cooling tunnels, soldering plants and drying ducts. Depending on the material, the belts can withstand operating temperatures from -80° C to +280° C.

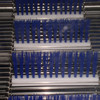

Our rod network belts are available in three product categories: The ECO is the economical version for standard applications, while the ELT (Extended Life Time), in which additional short individual meshes provide additional nodes and thus increased stability, can also withstand higher loads. Another advantage over the ECO is the much faster belt changes - splice times can be reduced by up to 80%.

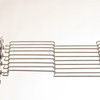

Last but not least, the rod network corner belts are the hygienic solution for changing direction or conveying hot products in curves.

Optionally, the belts can also be equipped with points, so that even demanding production processes are no problem. Combinations with guide chains and carriers are also possible. And that's not all, because the materials used also ensure flexibility in production: there is a choice of spring steel wire, stainless steel wire and our material innovation K2390. The latter is recommended wherever high demands are placed on corrosion resistance, for example when using fruit acids or aggressive cleaning agents.