Märtens conveyor belts GmbH from Flensburg

rod network belts, plastic conveyor belts, metal conveyor belts

Our products

- Separating belt

Description

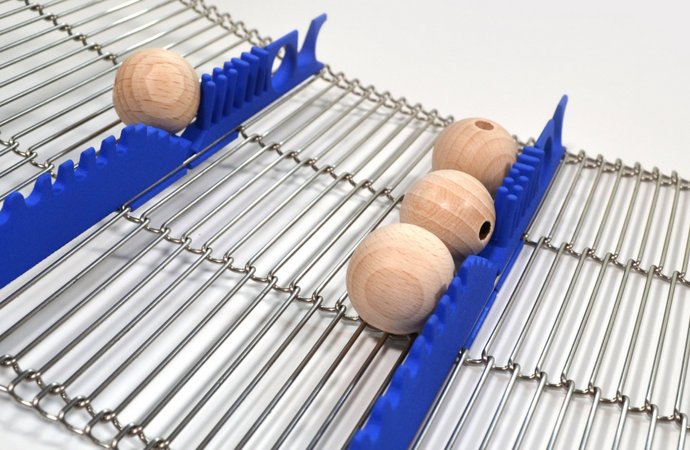

When it comes to spreading or merging products, our spreading belts come into play. The maximum spreading range is 30 %. In this way, product gaps can be increased or decreased even during ongoing transport. One example is the spreading of protein bars before the chocolate coating, so that the goods are prevented from sticking together. This applies even to the smallest articles or bulk goods. Another plus point is that no changeover is required when changing products.

Our spreader belts consist of a transversely elastic fabric with a silicone coating. A new material innovation is our spreader belt LW, which has a reduced force absorption. This makes belt installation much easier and also reduces downtimes during belt replacement.

Would you like to know exactly? No problem: You will find two videos under "Downloads". These show the reduction of product gaps or the increase of product gaps in longitudinal and transverse direction during ongoing transport. We also provide data sheets, assembly instructions and more here as practical PDF downloads.

By the way: As a special machine, you can also obtain spreading belt systems from us.

Application areas

- Separating or converging products in the production or packaging process

Materials

- Transverse elastic fabric with silicone coating

Accessories

min. Temperature

+10° C

max. Temperature

+50° C

Speeds

- Max. belt speed: 25 m/min

Dimensions

- Max. dimensions: L = approx. 8000 mm | W = approx. 1500 mm

- Separating range: 30 %

Videos

Downloads

- Assembly instructions ( PDF 80.06 KB )

- Separating belt HW ( PDF 273.16 KB )

- Separating belt LW ( PDF 156.39 KB )

- Product data sheet

Tech. drawings / sketches / data tables

- Separating belt

Description

When it comes to spreading or merging products, our spreading belts come into play. The maximum spreading range is 30 %. In this way, product gaps can be increased or decreased even during ongoing transport. One example is the spreading of protein bars before the chocolate coating, so that the goods are prevented from sticking together. This applies even to the smallest articles or bulk goods. Another plus point is that no changeover is required when changing products.

Our spreader belts consist of a transversely elastic fabric with a silicone coating. A new material innovation is our spreader belt LW, which has a reduced force absorption. This makes belt installation much easier and also reduces downtimes during belt replacement.

Would you like to know exactly? No problem: You will find two videos under "Downloads". These show the reduction of product gaps or the increase of product gaps in longitudinal and transverse direction during ongoing transport. We also provide data sheets, assembly instructions and more here as practical PDF downloads.

By the way: As a special machine, you can also obtain spreading belt systems from us.

Application areas

- Separating or converging products in the production or packaging process

Materials

- Transverse elastic fabric with silicone coating

Accessories

min. Temperature

+10° C

max. Temperature

+50° C

Speeds

- Max. belt speed: 25 m/min

Dimensions

- Max. dimensions: L = approx. 8000 mm | W = approx. 1500 mm

- Separating range: 30 %

Videos

Downloads

- Assembly instructions ( PDF 80.06 KB )

- Separating belt HW ( PDF 273.16 KB )

- Separating belt LW ( PDF 156.39 KB )

- Product data sheet