Märtens conveyor belts GmbH from Flensburg

rod network belts, plastic conveyor belts, metal conveyor belts

Our products

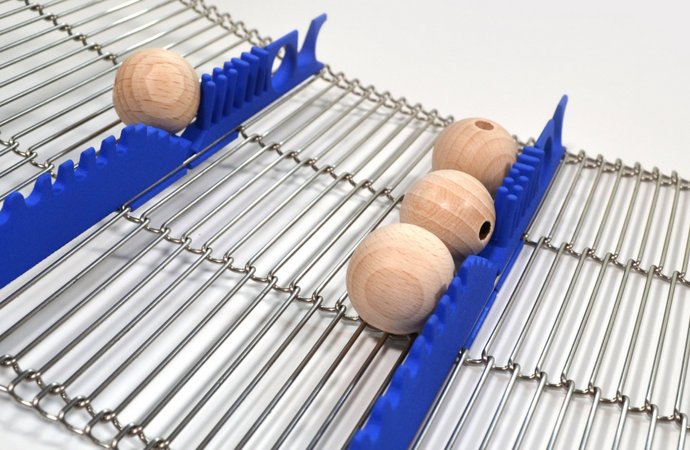

conveyor belts

- Plastic conveyor belts

Industries

- Food

- Hygiene products industry

- Printing industry, folding boxes and cartons

Application areas

- Conveyor machines

- Linear units

- Packaging equipment

Materials

- Duroplastic (PU)

- Kevlar tension members

- Steel tension members

- Thermosplatic PU

- Without added recycled materials

Special versions

- Coating as requested and depending on application

- Surface ground or milled

- Variable tooth and splice distribution

- With cleats

- With profiles

min. Temperature

-20° C

max. Temperature

+80° C

Special features

- Chemical resistance to oils, greases and petrol,

- hydrolysis and ageing-resistant

Downloads

Tech. drawings / sketches / data tables

Machines & Components

- Plastic conveyor belts

Industries

- Food

- Hygiene products industry

- Printing industry, folding boxes and cartons

Application areas

- Conveyor machines

- Linear units

- Packaging equipment

Materials

- Duroplastic (PU)

- Kevlar tension members

- Steel tension members

- Thermosplatic PU

- Without added recycled materials

Special versions

- Coating as requested and depending on application

- Surface ground or milled

- Variable tooth and splice distribution

- With cleats

- With profiles

min. Temperature

-20° C

max. Temperature

+80° C

Special features

- Chemical resistance to oils, greases and petrol,

- hydrolysis and ageing-resistant